Over A Decade of Growth and Innovation

We’re proud to have been manufacturing from our current site in Leeds for over 10 years. Our 200,000 sq. ft facility near Elland Road now employs more than 300 people, each playing a vital role in keeping British manufacturing strong.

Step Inside the Facility

Our world class manufacturing facility is designed for precision, efficiency, and quality at every stage. From the moment aluminium arrives to the final product checks before dispatch, each step is handled with skill and care.

Managing Director Steve Bromberg explains:

“Our family would like to think we’ve helped show that British manufacturing is alive and well. It can thrive when done right, providing high-quality products without having to import them from halfway around the world.”

That dedication to keeping production here in the UK has become a cornerstone of our success, and something that impresses even the most experienced visitors. When renowned architect and TV presenter George Clarke visited the facility, he praised the scale and sophistication of the operation. He described the setup as “fantastic” and said it was brilliant to see such a well-established manufacturing facility operating here in the UK.

Aluminium Storage & Supply

The process begins in our aluminium storage area, where we hold up to £2 million worth of stock at any one time. We source aluminium from leading system houses across Europe, receiving daily deliveries to ensure we always have a steady supply of the finest materials. This approach keeps our quality consistent and our lead times reliable, something our customers know they can depend on.

Quality Checking & Taping

Before any fabrication begins, the aluminium profiles pass through checking and taping. Here, technicians inspect every profile, checking for imperfections and ensuring that the powder coating meets our high standards for colour and finish. Their attention to detail at this stage ensures that only flawless materials move on to the next phase of production.

Precision Machining

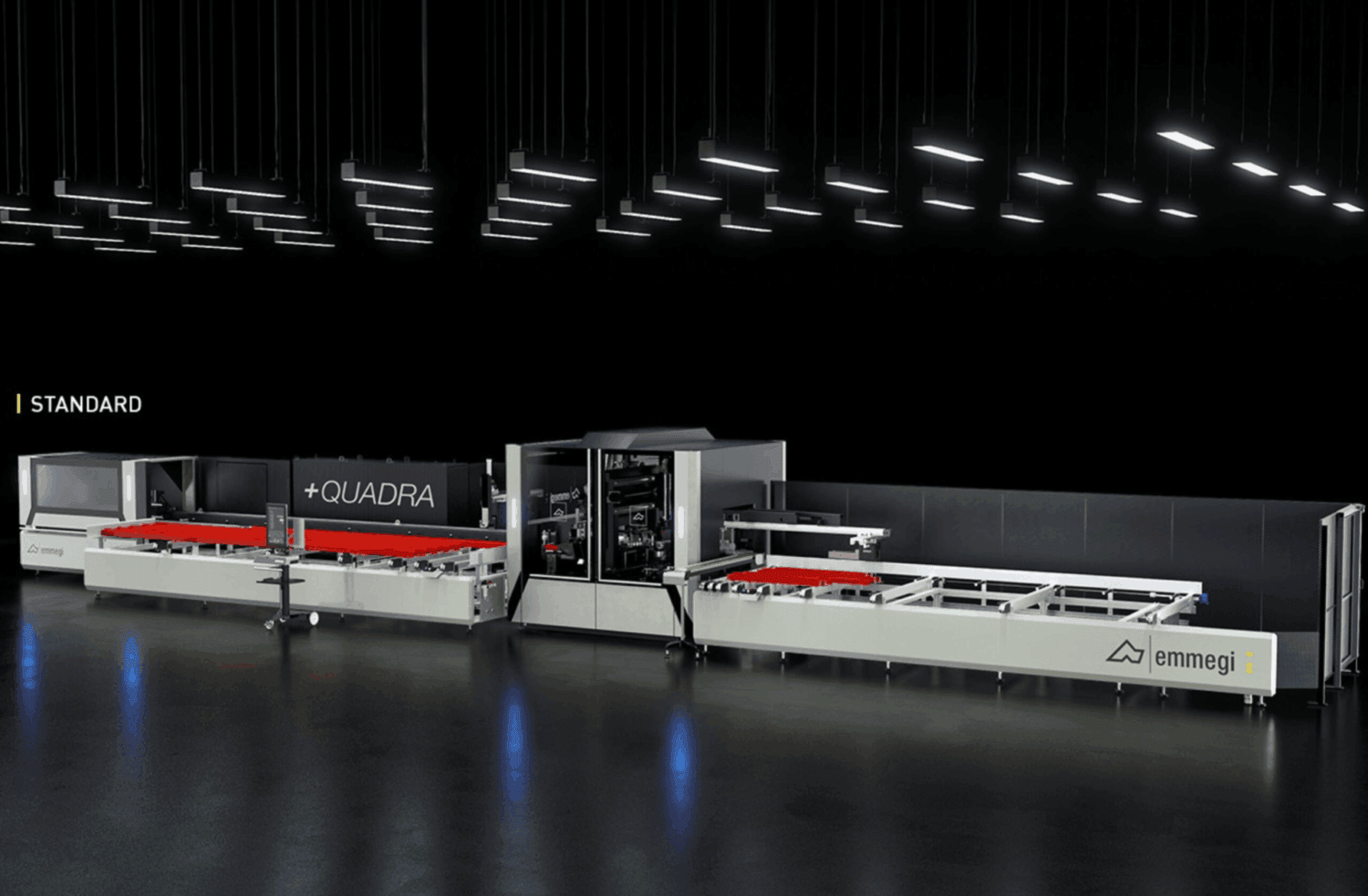

Once approved, the aluminium moves into our machining space, the heart of our operation and a true reflection of our commitment to innovation. This is where precision meets performance, powered by cutting-edge CNC technology.

In 2024 we became the first fabricator in the UK to order the latest Emmegi +Quadra 20-axis CNC, further cementing ourselves as market leaders. This advanced system delivers 360° rotary milling, drilling, and tapping on all four faces of the profile, combined with a 360° rotary cutting blade, achieving unmatched accuracy and efficiency. After reviewing machining centres from every major manufacturer, nothing matched its performance.

Before any product leaves the machining area, it undergoes a final inspection, is individually wrapped, and prepared for dispatch. Quality control is built into every stage, ensuring each frame meets the highest standards of precision and finish.

Glass Storage & Preparation

To complement our aluminium work, we also receive glass from some of the world’s most respected manufacturers. Each delivery is carefully cleaned, inspected, and tested against glazing regulations and our internal standards.

Once approved, it’s stored in our dedicated glass storage space, ready to be fitted into our doors and rooflights. This level of control ensures the clarity, strength, and safety of every pane that leaves our site.

Pre-Made & Stock Options

Thanks to our scale, we’re able to hold an extensive range of stock, typically around 200 to 300 doors ready for immediate turnaround within just five business days.

We achieve this efficiency by batching orders and mass-producing aluminium profiles in one go, which significantly reduces material waste and streamlines production. Our stock bifold doors offer the same premium Express quality you’d expect, but with a faster turnaround and more competitive price, as we cut out the middleman and pass the savings directly to you.

British Craftsmanship at Its Best

Our investment in people, technology, and materials has allowed us to build a facility that represents the very best of British craftsmanship. By keeping production here in the UK, we maintain complete control over quality, precision, and delivery, while supporting local jobs and skills. As Managing Director Steve puts it, that’s what makes our work truly special:

“It’s about doing things the right way. We’re proud to manufacture here in Leeds and proud that every product we make carries that mark of British quality.”

When it comes to investing in high-quality home features, seeing them in person makes all the difference. You can feel the expertise, check the finishes, and truly understand what sets our products apart. Visit our Leeds showroom to explore our range and take a guided tour of our manufacturing facility. While you’re here, you can also discover more bespoke solutions from our sister company, Express Bi-Folding Doors.

Alternatively, explore our virtual showrooms anytime from the comfort of your home. From the first piece of aluminium to the final inspection, every product we manufacture is built with care, skill, and pride. It’s this commitment to excellence that continues to set Express Direct apart.